| Manufacturing Capabilities | Typical | Advanced | |

|---|---|---|---|

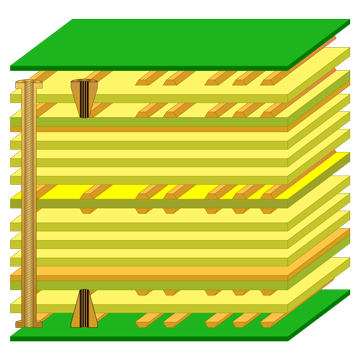

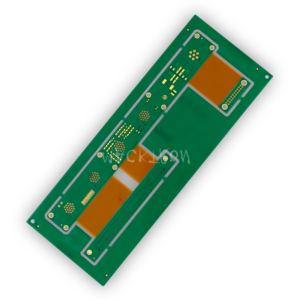

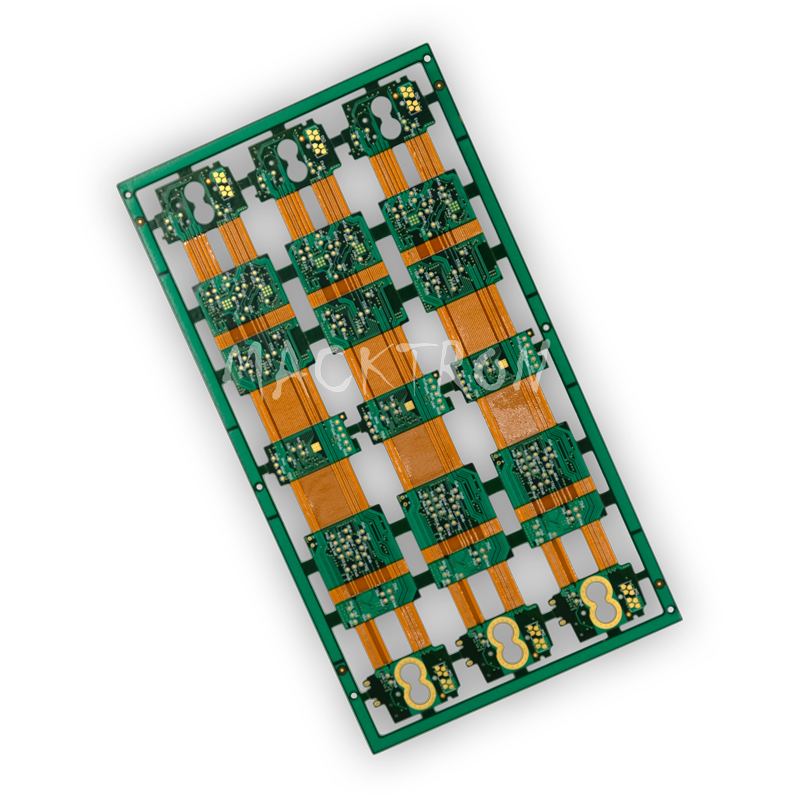

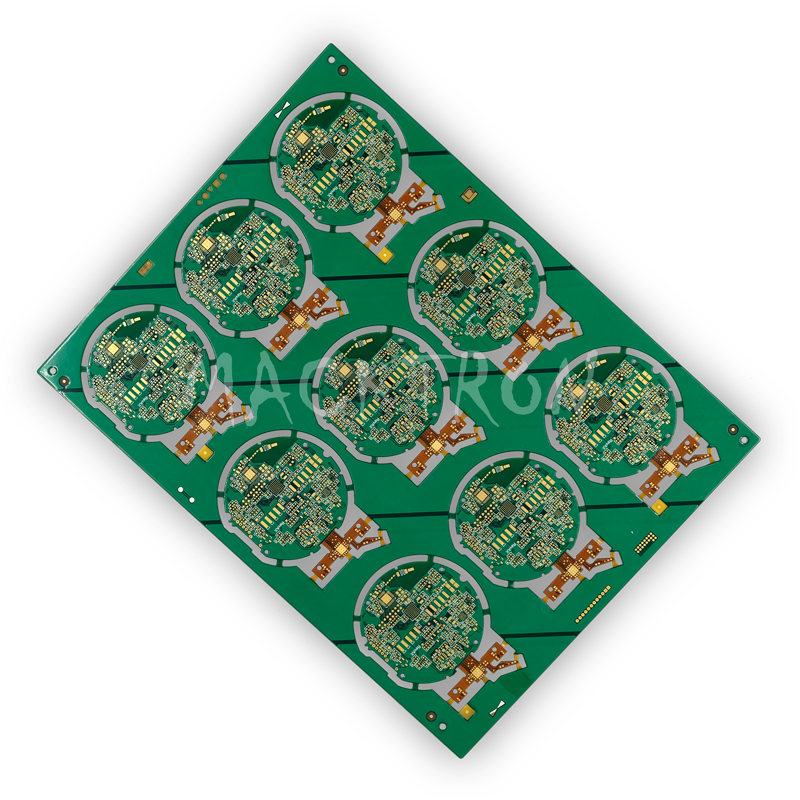

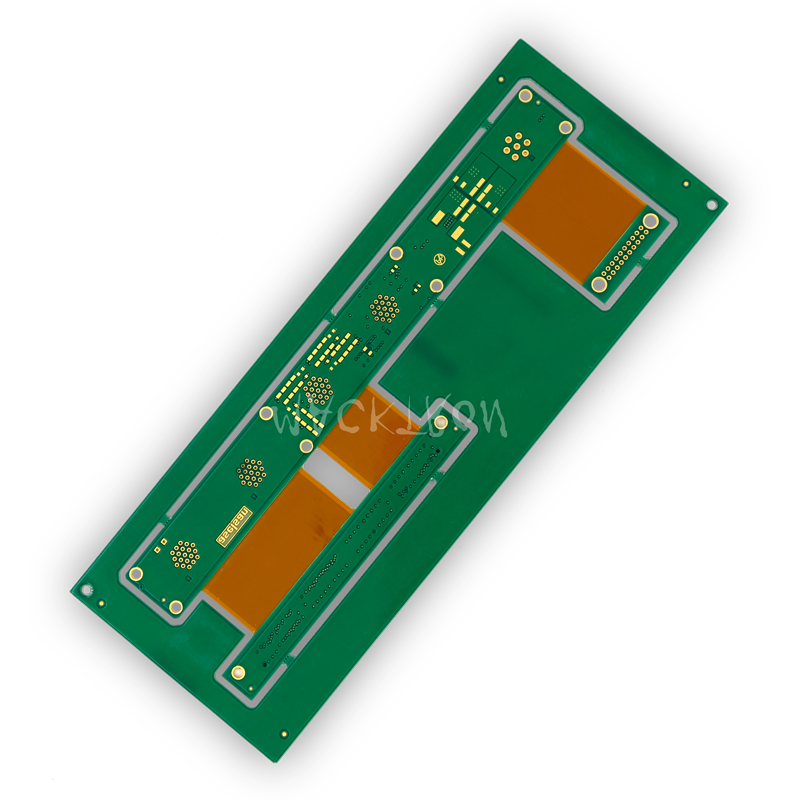

| Product Structure | Rigid-Flex Structure | N+F+N | F+N N+F+N 1+F+1 |

| Base Material | Flex Material | PI | PI PET LCP |

| Rigid Material | High Tg FR4 | High Tg FR4 PTFE Ceramics |

|

| Stiffener Material | PI, FR4, Stainless Steel, Aluminum | PI, FR4, Stainless Steel, Aluminum | |

| Flexible Coating | Coverlay | Coverylay Flex Solder Mask |

|

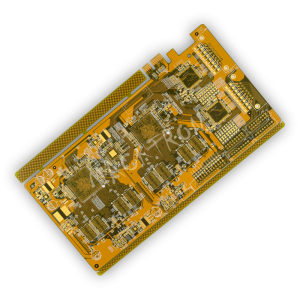

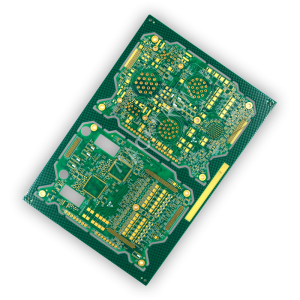

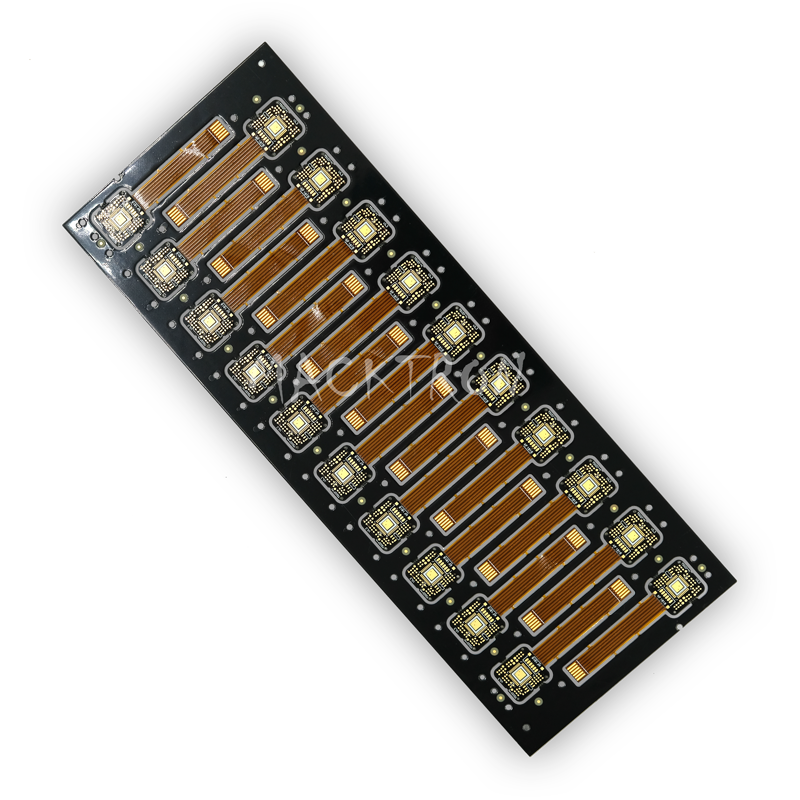

| Color | Rigid Section | Green (Matt/glossy), Yellow, Black (Matt/glossy), Blue, Red, White, Orange | Green (Matt/glossy), Yellow, Black (Matt/glossy), Blue, Red, White, Orange |

| Flex Section | Yellow, Black | Yellow, Black, White | |

| Layer Count | Rigid Section | 12 | 18 |

| Flex Section | 4 | 6 | |

| Board Thickness | Rigid Section (Includes Flex layer) | 0.5mm-5.0mm | 0.3mm-7.0mm |

| Flex Section | 0.15-0.3mm | 0.1-0.4mm | |

| Dimensions | Max. Brd. Size | 220mm*380mm | 220mm*380mm |

| Min. Brd. Size | 20*20mm (In-board tooling holes) | 10*10mm | |

| Dimensional Tolerance | Rigid Section | +/-0.15mm | +/-0.1mm |

| Flex Section | +/-0.1mm | +/-0.05mm | |

| Max. Copper Thickness | Inner Layer | 1 OZ | 2 OZ |

| Outer Layer (Flex part in inner layer) | 3 OZ | 8 OZ | |

| Hole-to-Flexible Distance | Hole-to-Flexible Distance | 1.5mm | 1.0mm |

| Aspect Ratio | Rigid Section | 12:01 | 16:01 |

| Min. Dielectric Thickness | Inner Layer Flex Core | 0.025mm | 0.0125mm |

| Inner Layer Rigid Core | 0.1mm | 0.075mm | |

| Prepreg Type | 1080 | 106 1080 |

|

| Surface Finish | RoHS Compliant | HAL (leadfree), Immersion Nickel Gold Galvanic Nickel Gold, Immersion Tin Immersion Silver, Hard Electroplated Gold for Contacts Chem. Nickel Palladium Gold, OSP Immersion Nickel Gold + OSP, HAL (leadfree) + Gold Fingers Immersion Nickel Gold + Gold Fingers, OSP + Gold Fingers |

HAL (leadfree), Immersion Nickel Gold Galvanic Nickel Gold, Immersion Tin Immersion Silver, Hard Electroplated Gold for Contacts Chem. Nickel Palladium Gold, OSP Immersion Nickel Gold + OSP, HAL (leadfree) + Gold Fingers Immersion Nickel Gold + Gold Fingers, OSP + Gold Fingers |

| Non-RoHS Compliant | H.A.L. Leaded | H.A.L. Leaded | |

软硬结合板beaglebone2019-03-11T10:43:26+00:00