| Manufacturing Capabilities | Typical | Advanced | |

|---|---|---|---|

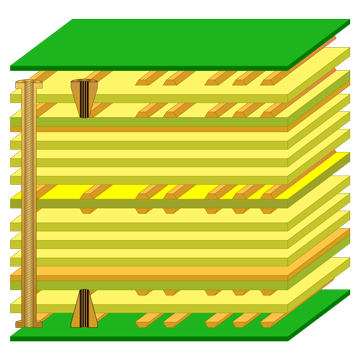

| Capabilities | Layer Count | 2L - 68L | 2L - 68L |

| Base Material & Matching Prepreg | FR-4 (Standard/medium/high Tg, Different CTI, Halogen Free, CAF Resistant), RF materials (Rogers, Taconic, Arlon, BT etc), PTFE | FR-4 (Standard/medium/high Tg, Different CTI, Halogen Free, CAF Resistant), RF materials (Rogers, Taconic, Arlon, BT etc), PTFE | |

| Finished Brd. Thk. | 0.30 mm - 10.00 mm | 0.20 mm - 10.00 mm | |

| Finished Copper Wt. | 0.5 oz - 10.0 oz (External), 0.25 oz - 4.00 oz (Internal) | 0.5 oz - 10.0 oz (External), 0.25 oz - 9.00 oz (Internal) | |

| Min. Brd. Size | 20.00 mm * 20.00 mm (In-board tooling holes) | 10.00 mm * 10.00 mm | |

| Max. Brd. Size | 23" * 30"(2L), 22" * 28"(≥4L) | 23" * 30"(2L), 22.5" * 30"(≥4L) | |

| Surface Finish | RoHS Compliant | HAL (leadfree), Immersion Nickel Gold Galvanic Nickel Gold, Immersion Tin Immersion Silver, Hard Electroplated Gold for Contacts Chem. Nickel Palladium Gold, OSP Immersion Nickel Gold + OSP, HAL (leadfree) + Gold Fingers Immersion Nickel Gold + Gold Fingers, OSP + Gold Fingers |

HAL (leadfree), Immersion Nickel Gold Galvanic Nickel Gold, Immersion Tin Immersion Silver, Hard Electroplated Gold for Contacts Chem. Nickel Palladium Gold, OSP Immersion Nickel Gold + OSP, HAL (leadfree) + Gold Fingers Immersion Nickel Gold + Gold Fingers, OSP + Gold Fingers |

| Non-RoHS Compliant | H.A.L. Leaded | H.A.L. Leaded | |

| Finish Coating Thk. | Aspect Ratio for H.A.L | ≤5:1(plated hole dia. ≥ 0.30 mm) | ≤5:1(plated hole dia. ≥ 0.30 mm) |

| H.A.L.(leaded & lead-free) | 1 um - 40 um | 1 um - 40 um | |

| OSP | 0.2 um - 0.4 um | 0.2 um - 0.4 um | |

| Immersion Nickel Gold | 3 um - 5 um(nickle), 1 uin - 3 uin(gold) | 3 um - 5 um(nickle), 1 uin - 4 uin(gold) | |

| Chem. Nickel Palladium Gold | ≥ 5 um(nickle), 1 uin - 6 uin(palladium), 1 uin - 6 uin(gold) | ≥ 5 um(nickle), 1 uin - 6 uin(palladium), 1 uin - 6 uin(gold) | |

| Immerison Silver | 6 uin - 12 uin | 6 uin - 12 uin | |

| Immersion Tin | ≥ 1 um | ≥ 1 um | |

| Galvanic Hard Gold | 5 uin - 40 uin | 5 uin - 80 uin | |

| Gold Finger/Connector | 1 uin - 40 uin | 1 uin - 80 uin | |

| Blue Mask Thk. | 0.20 mm - 0.60 mm | 0.20 mm - 0.60 mm | |

| Carbon Ink Thk. | 10 um - 50 um | 10 um - 50 um | |

| Drill/Hole | Through Hole Aspect Ratio | 28:1(drill dia. ≥ 0.30 mm) | 28:1(drill dia. ≥ 0.30 mm) |

| Microvia Aspect Ratio | 0.8:1 | 1:01 | |

| Min. Mechanical Drill | 0.20 mm | 0.10 mm | |

| Max. Mechanical Drill | 6.30 mm | 6.30 mm | |

| Mechanical Blind Drill | 0.20 mm - 0.50 mm | 0.20 mm - 0.70 mm | |

| Min. Laser Drill | 0.10 mm (Single PP1080 thk.) | 0.10 mm (Single PP1080 thk.) | |

| Max. Laser Drill | 0.15 mm (Single PP3313 thk.) | 0.15 mm (Single PP3313 thk.) | |

| Min. Drill for Material PTFE/PTFE Composite | 0.30 mm | 0.30 mm | |

| Min. Half Hole Drill | 0.50 mm | 0.50 mm | |

| Min. Overlapped Drill | 0.45 mm | 0.45 mm | |

| Min. Backdrill | 0.50 mm | 0.50 mm | |

| Min. Dielectric Thk. for Backdrill | 0.20 mm | 0.20 mm | |

| Max. Hole for Bluemask Plugging | 5.00 mm | 5.00 mm | |

| Max. Hole for Soldermask Plugging | 0.65 mm | 0.65 mm | |

| Hole for Epoxy Fill | 0.10 mm - 0.45 mm | 0.10 mm - 0.70 mm | |

| Counter Bore/Sink Hole Angle | 130°(dia.≤3.175 mm), 165°(dia. 3.175 mm - 6.300 mm) | 82°, 90°, 100°, 135°(dia. 3.175 mm - 6.300 mm) | |

| Min. Mechanical Drill for Different Brd. Thk. | 0.15 mm(brd. thk. ≤ 0.80 mm) | 0.10 mm(brd. thk. ≤ 0.80 mm) | |

| 0.15 mm(brd. thk. ≤ 1.40 mm) | 0.15 mm(brd. thk. ≤ 1.20 mm) | ||

| 0.20 mm(brd. thk. ≤ 2.80 mm) | 0.20 mm(brd. thk. ≤ 2.80 mm) | ||

| Hole Position Tol. | ±3 mil | ±3 mil | |

| PTH Dia. Tol. | ±3 mil | ±3 mil | |

| NPTH Dia. Tol. | ±2 mil | ±2 mil, +2 mil - 0 mil, 0 mil - (-2) mil | |

| Pressfit Hole Dia. Tol. | ±2 mil | ±2 mil | |

| Drilled Slot Hole Tol. | ±0.05(L)/0.05(W) mm(unplated) ±0.13(L)/0.10(W) mm(plated) |

±0.05(L)/0.05(W) mm(unplated) ±0.13(L)/0.10(W) mm(plated) |

|

| Milled Slot Hole Tol. | ±0.10(L)/0.10(W) mm(unplated) ±0.13(L)/0.13(W) mm(plated) |

±0.10(L)/0.10(W) mm(unplated) ±0.13(L)/0.13(W) mm(plated) |

|

| Backdrill Depth Tol. | ±4 mil | ±4 mil | |

| Counter Bore/Sink Hole Angle Tol. | ±10° | ±10° | |

| Counter Bore/Sink Hole Dia. Tol. | ±0.20 mm | ±0.20 mm | |

| Counter Bore/Sink Hole Depth Tol. | ±0.15 mm | ±0.15 mm | |

| Inner Layer Base Copper VS Line Width/Space | 18um (1/2OZ) | 3/3mil | 2.5/2.5mil |

| 35um (1OZ) | 3.5/3.5mil or 3/4mil | 3.5/3.5mil or 3/4mil | |

| 70um (2OZ) | 5.5/5.5mil | 5.5/5.5mil | |

| 105um (3OZ) | 6.5/6.5mil | 6.5/6.5mil | |

| 140um (4OZ) | 8/8mil | 8/8mil | |

| 175um (5OZ) | 10/10mil | 10/10mil | |

| 210um (6OZ) | 12/12 mil | 12/12 mil | |

| Outer Layer Base Copper VS Line Width/Space | 7-9um | 3/3mil | 3/3mil |

| 12um | 3.5/3.5mil | 3.5/3.5mil | |

| 18um (1/2OZ) | 4.5/4.5mil | 4.5/4.5mil | |

| 35um (1OZ) | 5/5mil | 5/5mil | |

| 70um (2OZ) | 9/9mil | 8/8mil | |

| 105um (3OZ) | 10/10mil | 10/10mil | |

| 140um (4OZ) | 13/13mil | 10/13mil | |

| 175um (5OZ) | 14/14mil | 12/15mil | |

| Copper Feature | Min. Annular Ring | 4 mil | 4 mil(partially 3.5 mil) |

| Min. BGA Pad Dia. | 10 mil(excluding H.A.L) | 8 mil(excluding H.A.L) | |

| Min. BGA Pad Dia. for Leaded H.A.L. | 10 mil | 10 mil | |

| Min. BGA Pad Dia. for Lead-free H.A.L. | 12 mil | 12 mil | |

| Min. Pad Size for H.A.L. | 7 mil * 16 mil | 7 mil * 16 mil | |

| Solder Mask | Color | Green(matt/glossy), Yellow, Black(matt/glossy), Blue, Red, White, Orange | Green(matt/glossy), Yellow, Black(matt/glossy), Blue, Red, White, Orange |

| Min. Soldermask Web | 0.10 mm | 0.075 mm | |

| Min. Soldermask to Pad Clearance | 0.10 mm | 0.10 mm | |

| Min. Soldermask Track Cover | 0.10 mm | 0.10 mm | |

| Soldermask Thk. on Copper | 10 um - 18 um | 10 um - 18 um | |

| Soldermask Thk. at Shoulder | ≥ 5 um(one-time printing) | ≥ 5 um(one-time printing) | |

| Soldermask Thk. over Hole | ≥ 5 um | ≥ 5 um | |

| Legend | Color | White, Yellow, Black, Orange | White, Yellow, Black, Orange |

| Min. Stroke Width | 0.17 mm | 0.17 mm | |

| Min. Height for Legibility | 1.00 mm | 1.00 mm | |

| Min. Legend to Pad Clearance | 4 mil | 4 mil | |

| Profiling | Panelization | V-score, Tab-routing, Tab-routing & Perforation, Tab-routing & V-score, Tab-routing & V-score & Perforation |

V-score, Tab-routing, Tab-routing & Perforation, Tab-routing & V-score, Tab-routing & V-score & Perforation |

| V-score Angle | 20°, 30°, 60° | 20°, 30°, 60° | |

| Brd. Thk. for Double-side V-score | 0.80 mm - 3.20 mm | 0.80 mm - 3.20 mm | |

| Brd. Thk. for Single-side V-score | 0.60 mm - 0.80 mm | 0.60 mm - 0.80 mm | |

| Min. Inside Corner Radius | 0.40 mm | 0.30 mm | |

| Gold Fingers/Edge Connectors | Edge Beveling Angle | 30°, 45° | 30°, 45° |

| Edge Chamfering Corner | 45° | 45° | |

| Min. Notch Width beside Edge Connector | 0.20 mm | 0.20 mm | |

| Edge Beveling Depth | 0.50 mm | 0.50 mm | |

| Min. Finger Top to Copper Distance | 3.00 mm | 2.00 mm | |

| Min. Finger Bot. to Brd. Outline | 7.00 mm | 6.00 mm | |

| Min. Finger to Finger Clearance | 6 mil | 5 mil | |

| Edge Beveling Angle Tol. | ±5° | ±5° | |

| Edge Beveling Remaining Thk. Tol. | ±5 mil | ±5 mil | |

| Profile | Brd. Dimension Tol. | ±0.10 mm | ±0.10 mm |

| Inside Cutout Position Tol. | ±0.10 mm | ±0.10 mm | |

| V-score Angle Tol. | ±5° | ±5° | |

| V-score Web Thk. Tol. | ±0.05 mm | ±0.05 mm | |

| V-scores Offset Tol. | ±0.10 mm | ±0.10 mm | |

| Others | Brd. Thk. for Epoxy Fill | 0.50 mm - 6.50 mm | 0.40 mm - 6.50 mm |

| Min. Channel for Internal Split Plane | 8 mil | 8 mil | |

| Bow & Twist | 0.75% | 0.50% | |

| Brd. Thk. Tol. | ±0.10 mm(thk.≤1.00 mm), ±10%(thk.>1.00 mm) | ±0.10 mm(thk.≤2.00 mm), ±0.15(2.10≤thk.≤3.00 mm) | |

| Impedance Control Tol. | ±5Ω(<50Ω), ±10%(≥50Ω) | ±5Ω(<50Ω), ±8%(≥50Ω) | |

| Trace Width/Space Tol. | ±1.0 mil(≤10 mil), ±1.5 mil(>10 mil) | ±1.0 mil(≤10 mil), ±1.5 mil(>10 mil) | |

| Layer to Layer Registration Tol. | ≤2 mil | ≤2 mil | |

| Min. Trace Width/Space for Epoxy Fill | 4.0 mil / 4.0 mil | 3.5 mil / 3.5 mil | |

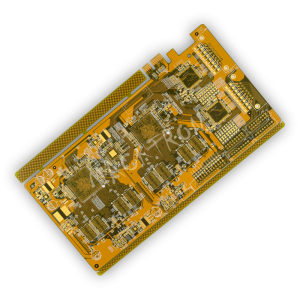

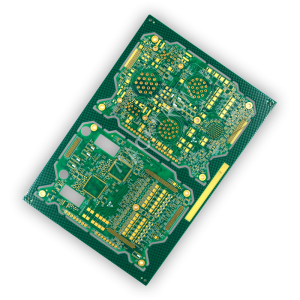

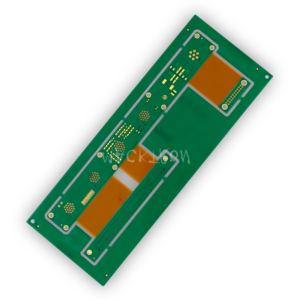

硬板beaglebone2021-04-09T08:47:06+00:00